Whole Life Carbon approach to building design leads to a fundamental shift with a far higher impact on carbon emission reduction than an energy neutral design approach.

Linus Klaassen and Peter Buurman sustainability consultants at Deerns make the case for Whole life Carbon (WLC) approach to simplify the over-complicated process of current sustainability measuring tools.

Cost analysis in emissions

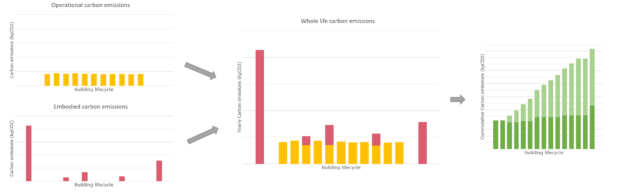

Linus and Peter strongly advise a WLC analysis which is based on CO2 emissions with a separate CO2 indicator rather than the Life Cycle Analysis which is based on euros. Aside from being aligned to EU targets, another benefit is that aCO2 indicator would track a property’s emissions and energy use changes over the entire building life cycle as part of the WLC approach. “It’s a matter of weighing up both energy and material emissions,” says Buurman.

A separate CO2 indicator makes it easier to have single goal for sustainability: the lowest CO2 emissions possible. This integrated assessment simplifies the measurement of a building since it effectively weighs up the entire building and material-related emissions in a single figure.

“The plethora of methods for measuring sustainability is unnecessarily complicated and time consuming. Using a separate CO2 indicator would simplify everything since it this single figure alone would represents the overall emissions, and hence the sustainability of the building,” says Klaassen.

“Designing an energy-perfect building shouldn’t come at the cost of ignoring emission from materials used in constructing it. If we use the WLC or CO2 indicator as a standard for sustainability we can base decisions on the total CO2 emissions over the entire life of a building,” adds Buurman.

Buurman is effectively encouraging a huge step up in approach found in the current Energy Performance of Buildings (EPG) and Environmental Performance of Buildings standards in the Netherlands, which are based on EU standards. By implication, this would render these and similar building performance standards redundant by virtue of being void of any reference to environmental damage of emissions from materials and energy use.

WLC Case Study: Parel in de Polder

“The best design incorporates low emission products in terms of energy as well as material. This is not the outcome you will achieve by, for example, following the Nearly Zero Energy Buildings (NZEB) standards where the highest possible energy performance is the main performance criteria. The NZEB ignores the fact that each millimetre of insulation material or heat pump which increases the embodied carbon of a building, hence the whole life cycle CO2 emission,” says Klaassen.

This is why the WLC approach informed the process for designing Parel in de Polder project De Vries en Verburg. Deerns took on the design of installations, building physics and materials alongside the NZEB and EPG consultants. “By putting designers and engineers together from the start we all had more insightful and better decision making. We could immediately see the impact of any modification,” says Buurman. Klaassen adds: “In the project, transparency on the total environmental impact proved critical to success. Consequently, materials which would usually have been excluded from the environmental performance equation, such as a large part of the solar panels are now included.”

“The result is solar-powered energy with the lowest possible material use. What an inspiring and energising process,” Buurman comments.

" The result is solar-powered energy with the lowest possible material use. What an inspiring and energising process

Projects deserve a WLC approach

Every design team deserves the WLC approach and a WLC advisor who sets the carbon emission baseline and desired targets against which the architects can then work. The design team then sets the baseline for materials.

A design team following the overall WLC approach would first set the carbon emission baseline for the combined impact of material and energy using the CO2 indicator. The next step would be to identify and set individual benchmarks for monitoring specific energy and material emissions. The architect, structural engineer and installation designers can include the benchmarks as requirements for the design. “The WLC advisor should joins the project from the start of the design process where the first choices are made since design teams since there is still far too little appreciation of value of the Whole Life Carbon approach,” says Buurman.

Klaassen adds: “At an advanced design stage it’s too late often means that many design choices are already fixed. Think about the orientation of a building or the choices for the façade design. When the outline design has already been shared with and approved by the client, there is no turning back.”

Buurman: “It is still a learning process, because it is not always clear which choice is better or worse for WLC. Admittedly, we need more knowledge and experience and we will also train people to be WLC experts. WLC consultants can come from any design discipline. “The most important thing is that the professionals consider design in an interdisciplinary way and come up with a calculation that takes all emission aspects into account,” concludes Klaassen