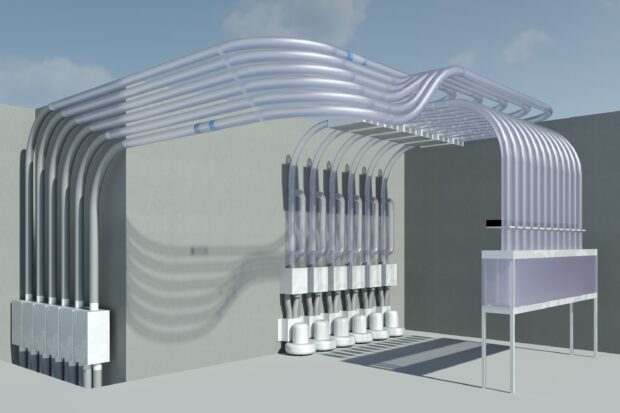

Pneumatic tube systems

Pneumatic tube systems offer a fast, safe and reliable way to move small goods across buildings, supporting logistics in hospitals, labs and distribution centres, among many others. Deerns designs advanced systems that boost efficiency and fit seamlessly into modern operations.

Custom solutions for modern demands

Pneumatic tube systems are increasingly used in various industries to support the logistical process. Installations must ensure high transport quality, fast handling times, high reliability and capacity that meets demand. At Deerns, we consult with our clients to design bespoke, next gen installations that support their processes and business values. We provide a full service from design and specification. We have also developed our own simulation programme to test designs, ensuring seamless transport.

How it works

A pneumatic tube system uses air pressure to transport containers through a network of tubes and diverters between stations. A central PC coordinates dispatches. Large setups use linear couplers to manage multiple lines and streamline transfers.

Applicability

Pneumatic tube systems are widely used in hospitals, distribution centres and laboratories, among others. Delicate, liquid-tight, hazardous or radioactive transports require special care, ensuring that samples always arrive undamaged.

Economically responsible

In a tight labour market, pneumatic tube systems offer a cost-effective solution – boosting efficiency by saving time on transporting small goods. With low upfront costs and a short payback period, they streamline operations and support business needs.

" With a pneumatic tube system, it’s like having a courier who moves through the building unhindered – no delays from doors, elevators, or other obstacles.