Deerns will be supporting STMicroelectronics in pursuing the semiconductor giant's target of carbon neutrality by 2027.

STMicroelectronics (STM) is a multinational technology powerhouse pioneering semiconductor technologies with a company pledge to achieve carbon neutrality by 2027. Deerns’ appointment to identify measures to execute this pledge at three STM facilities in Italy underscores Deerns’ commitment to pacesetting sustainability initiatives within the semiconductor industry.

" For Deerns, this carbon neutrality project signifies a significant milestone in our quest towards a smarter, greener and cleaner future. We will continue to offer our ongoing support to the semiconductor sector to attain its net zero targets.

Richters and Fabio Fasanella, Deerns project manager are leading the Deerns team in completing a feasibility study of identified measures set to be implemented. The primary focus is meeting CO₂ targets while assessing return on investment (ROI) and impact on business operations. Upgrading existing chiller systems, which are crucial for maintaining the controlled temperature of production areas at 21°C, is also underway.

The emphasis lies on energy recovery systems to reuse heat in the HVAC systems of cleanrooms.

Carbon Neutrality Projects in Italy

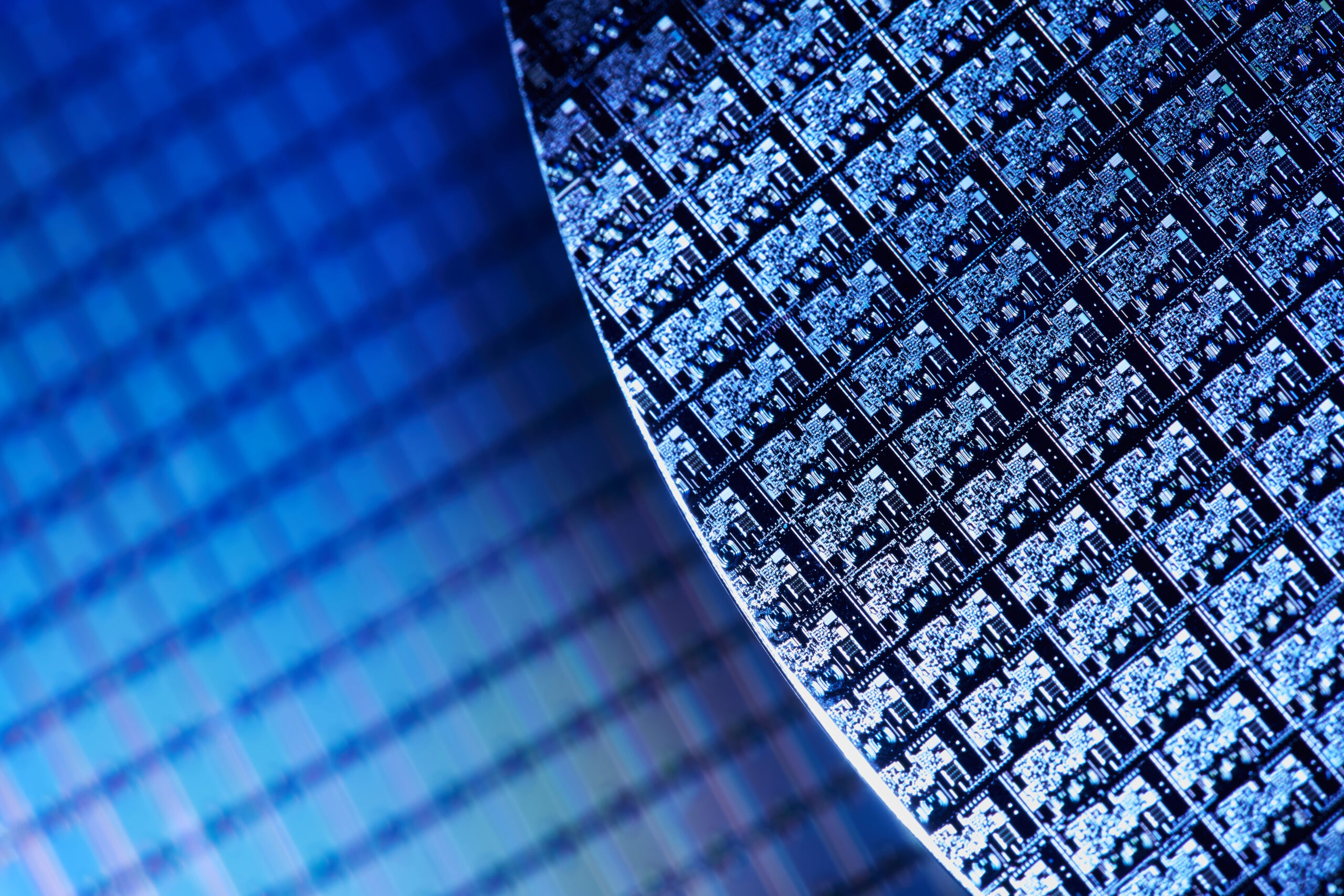

STMicroelectronics operates production facilities in Agrate, Castelletto and Catania in Italy featuring a combined area of over 60,000 m2 of cleanrooms. The increase in production capacity in the semiconductor sector has inevitably led to a corresponding rise in construction and operating emissions. Semiconductor manufacturing firms being urged to intensify their efforts in curbing greenhouse gas emissions and strive towards achieving net-zero carbon footprints across their entire supply chains. In STM’s uncompromising pursuit of net zero emissions, strategic measures entail:

- Reducing direct emissions via abatement and replacement strategies

- Enhancing electrical energy efficiency and adopting clean energy sources

- Leveraging the supply chain, including the management of raw materials, chemicals and gases, aimed at mitigating emissions across the entire value chain.

Best Practice and Innovation

The essence of innovation lies in embracing a holistic methodology to reduce energy consumption of chillers while addressing heat transfer intricacies. All systems must synergise seamlessly to achieve significant reductions in carbon emissions, a feat made possible through our comprehensive approach that prioritises best practices over high-tech solutions.

Richters explains, “Heating and cooling strategies for this project centre mostly on maximising energy savings. Looking ahead, the integration of smart building and process systems may emerge as the next frontier in master planning facility reconstruction or replacement.

“Adopting such innovations poses inherent challenges within existing facilities, given the intricate interconnections present. However, we view the journey towards smart infrastructure as an inevitable progression.”

All-inclusive Project Management

Solutions must align with proven technology, ensuring seamless integration without disrupting production continuity. To this end, collaboration with clients is paramount alongside close cooperation and intensive communication throughout the upgrade process. This entails adopting a practical and solution-oriented mindset.

The key challenges faced by the Deerns team include:

- Ensuring compliance by verifying that all requirements have been adequately fulfilled

- Obtaining accurate “as-built” information for existing facilities

- Understanding the client’s operations and the intricacies of existing systems

- Seamlessly integrating new initiatives with current systems

- Identifying, assessing, and mitigating risks

Given the inherent risks associated with upgrading existing facilities, meticulous project management is imperative. From initial design to project execution, validation, quality control and commissioning, the entire process is overseen by Deerns to ensure delivery of promised outcomes. Developing a comprehensive risk inventory, including mitigation strategies and monitoring the project post-handover to verify that targets are consistently met, underscoring Deerns’ holistic approach and commitment to the entire process.

Collaboration is Key

Deerns is renowned for its proactive stance in sharing information and knowledge acquired from decades of experience in the sustainability and electronics sectors. This approach is evident in Deerns’ collaboration with the STM project team.

Richter says, “Our emphasis on international cooperation combined with local partnerships enables us to create high end solutions best suited to local conditions. We have fully mapped STMicroelectronics’ production, purchasing and facilities processes, to ensure efficient communications and good relations at all levels.